norelem drive technology & drive elements

In machine construction and automation technology, many demanding power transmission and positioning tasks arise in everyday life. As a manufacturer of drive technology and drive elements, norelem offers various components in the online shop to meet the different drive technology requirements.

The norelem online shop consists of the product range of drive technology and drive elements from chains and sprockets, toothed belts, splined shafts and toothed belt pulleys, V-belts and V-belt pulley's, Gear wheels, gear racks and bevel gears, Worm screws and worm wheels and Transmissions.

What is drive technology?

Drive technology is generally understood to mean the supply of energy to a machine and the control of the various drive elements, i.e. the generation of movement by means of power transmission.

Application sectors for drive technology

Drive technology is used in machine construction and automation technology, e.g. in converters, motors, inverter cabinet systems, gearbox motors, couplings, generators, semiconductor technology, metrology machines, glass and wood processing machines and communications technology. In addition to these fields, drive technology is also used in the aerospace industry, machine tools, packaging machines and in medical technology.

Advantages of norelem drive technology

- Optimum power transmission

- Excellent positioning accuracy

- Standard components

- Long service life

- Low wear

- Quiet

- Positive fit power transmission

- Constant transmission ratios

- Vibration and noise reduction

Chains drive technology

A chain drive usually consists of sprockets, matching sprocket discs and a roller chain. In special cases, these components are supplemented by chain clamps and idler sprockets as required. Sprockets from norelem have been specifically developed for the machine construction sector and for industry. This is why the sprockets are available to buy from the online shop direct in many conventional sizes and versions.

Sprockets from norelem are resistant, robust, durable and manufactured acc. to DIN/ISO 606 standards. The teeth are milled and inductive hardened. The keyway is exactly aligned with a tooth tip. Most of the sprockets from norelem are pre-bored (ready for use) and easy to assemble. In addition to steel sprockets norelem also have stainless steel sprockets available from the online shop. These are used e.g. in the foodstuff industries.

As accessories, single chain links for the roller chains can also be reordered any time.

Toothed belt drives

Toothed belt systems consist of a toothed belt and two or more toothed belt pulleys. There are diverse advantages to a toothed belt system. When transmitting high forces by high accelerations, toothed belt systems ensure exact positioning and guarantee constant synchronisation. It also offers high energy efficiency and smooth running. Not only the standard sizes are available in the norelem range, toothed belts can also be ordered by the metre to suit the application.

Classic applications can be found in machine construction, automation technology and other branches. Gantry systems of high performance lasers, pick-and place units, rotary table systems or conveyor lines are just a few practical examples.

Toothed belt drives combine the positive characteristics of a chain and a flat belt, but require less maintenance. Toothed belt systems work quietly, very precisely and completely without slippage. The prerequisite for this is good harmonisation of the components. Another advantage over chain drives is the high acceleration values.

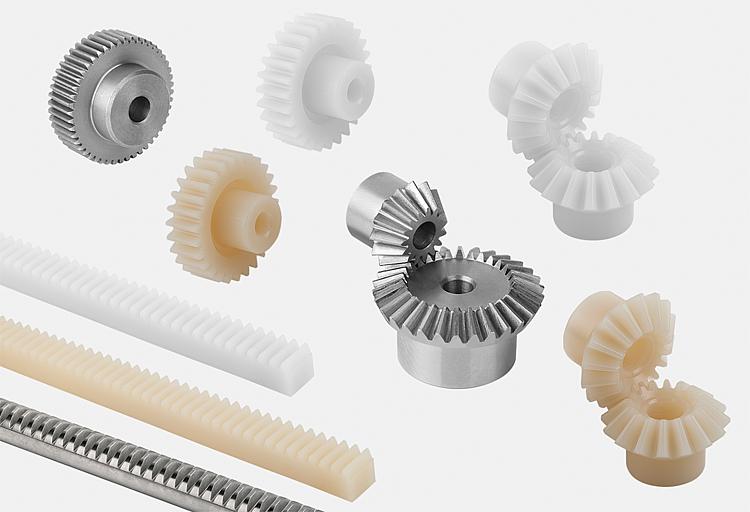

Gear wheels, gear racks and bevel gears

Gear wheel drives are the most common drive type used in machine construction. Gear wheel drives, i.e. gear wheels, gear racks and bevel gears, are used to transfer torque with a given speed from one shaft to another. To accomplish this different gear sizes are combined. By simply exchanging the individual gear wheels, another torque and speed ration can be achieved.

Compared to chain drives and belt drives, gear wheel drives from norelem have the advantage that smaller centre distances can be achieved. Much higher power transmissions can also be achieved when compared to belt drives.

Other advantages of gear wheels, ger racks and bevel gears are the slip-free and positive force transmission, the multitude of possible transmission ratios and the simple construction (low maintenance and reliability).

Gear wheel drives - Bevel gears

Cone shaped bevel gears are mostly used in transmission types where the shafts intersect at a given angle (mostly 90°) It is important here to keep the deflection of the contact pattern as small as possible under operating load. This is achieved by a small as possible centre distance from the tooth centre to the support bearing with a simultaneously large as possible shaft diameter. norelem offers bevel gears with these different ratios. The toothing is always straight and the bevel gears are all made from steel. The engagement angle is 20°.

Gear wheel drives - Spur gears

Spur gears, sometimes called straight-cut gears are the simplest and most common version of gear wheel. In drive technology spur gears are always used where high peripheral forces have to be transmitted.

When used in combination with a gear rack, rotary movements can be transformed into a linear movement (and vice versa). When designing a spur gearbox, horizontal shafts are preferred to vertical shafts. The shaft seating should be as precise as possible to ensure a long service life of the gears. Lubrication also functions best in the horizontal position. Attention should be paid to the parallelism of the shafts during installation so that misalignments are kept as low as possible. It is also important that the correct centre distances are maintained.

Worm drives / Worm gears

In machine and tool construction a worm screw is a shaft with one or more spiral(s) cut into it. When combined with a worm wheel they form a worm drive. The axes of the worm screw and the worm wheel intersect at 90°. Worm drives are ideal for translating large ratios into a slow speed.

Worm gears from norelem are suitable for continuous operation at high speeds and high torques.

Worm drives are mostly used where the drive should be low noise. Because of how thex are constructed worm gears are also highly robust. Efficiency is often not very high with high power ratios, since in addition to a rolling movement, a sliding movement (self-locking) is also required to drive the transmission.

Worm drives are often used for rolling processes or in presses as the drive. They find use in conveyor technology. High axial forces often occur where worm drives are used. This is mainly due to the fact that the worm screw is firmly mounted despite helical toothing.

Worm wheels from norelem are made from bronze. Worm screws are made from case-hardened and ground steel. The worm screws are all right-hand.

Gearboxes - Ready-to-install worm drives

Various types of ready-to-install transmissions are also available from norelem. All transmissions can be viewed around 360°. Our sales personal would be happy to answer any questions you may have about the transmissions.

The housings of the worm drive units are aluminium, the worm screws are steel and the worm wheels are a special brass alloy. The housings are anodised and the worm screws are case hardened.

The gearbox is universally applicable and, due to the encapsulated housing, maintenance-free. In addition, worm gears are very quiet and the power transmission is smooth. The worm drives can be mounted using simple screw fasteners. The transmission conforms to RoHs.

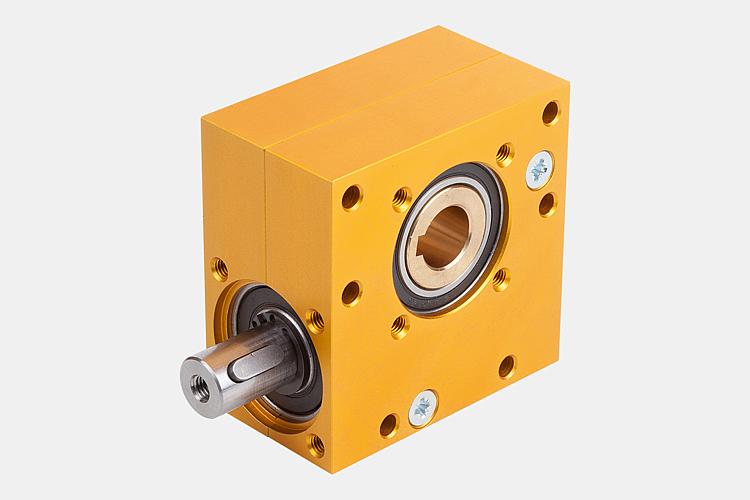

Gearboxes - Ready-to-install bevel gearboxes

There are three different types of ready-to-use bevel gear transmissions available from norelem.

- A bevel gearbox with a plastic housing

- A bevel gearbox with an aluminium housing

- A bevel gearbox with a die-cast zinc housing

The bevel gearbox with the plastic housing is especially suited for short term machine drives at low speeds or for manual operation. Rotation in both directions is possible. The bevel gearbox with aluminium housing and steel bevel gears is a high quality, universally applicable and maintenance-free transmission. There are seven sizes available from norelem. The ratio is always 1:1 and the direction of rotation is arbitrary. The transmission also has the advantage that it can be mounted in any position. The bevel gearbox with the die-cast zinc housing and steel bevel gears is ideal for drives with electric motors. In practice, these transmissions are mainly used as differential or distributor gearboxes. They are also used as an auxiliary gear drive for electric motors (i.e. for window blinds). All ready-to-install gearboxes from norelem conform to RoHs.