Ball lock pins from norelem

Ball lock pins are connecting elements that are used to securely connect and fasten components together. They are characterised by their self-locking function. This prevents the connection from loosening unintentionally, even under load.

Locking pins are used in various applications, e.g. in the machine construction industry, in agriculture or in vehicle construction. They offer a reliable, maintenance-free way of connecting components and preventing unintentional loosening.

When it comes to reliable connecting elements, the securing pins from norelem are a first-class choice!

Which ball lock pins are available?

What is a ball lock pin?

What is the difference between a ball lock pin and a socket pin?

How does a ball lock pin work?

Advantages of norelem ball lock pins

Different versions of ball lock pins

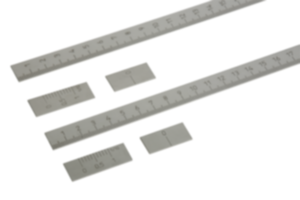

The securing pins from norelem are available in different versions to meet a wide range of requirements. The range is roughly divided into two types.

- Ball lock pins

- Socket pins

Other distinguishing features are the material of the base body, the pin diameter or the version itself.

Ball lock pins according to the "Base body material" category

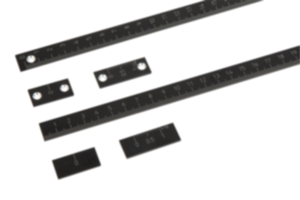

The ball lock pins are available in various materials. The base bodies are made of stainless steel, steel or thermoplastic.

It is important to carefully consider the advantages and disadvantages of each material to find the most suitable solution for your requirements.

While stainless steel has a high corrosion resistance and is ideal for humid environments, the steel locking pin may require additional protection in humid environments. The steel pin is less corrosion resistant than the stainless steel pin.

Steel, like stainless steel, is characterised by its high mechanical strength. Both materials are suitable for high loads. The ball lock pin made of thermoplastic, on the other hand, is less suitable for heavy loads due to its low mechanical strength.

In applications where weight savings are important, the ball lock pin made of thermoplastic is the first choice. The lightweight material thermoplastic is ideal for this, while steel and stainless steel increase the weight of the application.

In addition to other aspects such as electrical insulation, robustness and cost, each material has specific properties that can be advantageous for different applications. In summary, the choice between these materials depends on your specific requirements.

The pin diameter for ball lock pins

The ball lock pins can also be categorised according to pin diameter. Depending on the area of use, you can select the appropriate pin diameter to ensure the stability and safety of your connections.

The norelem range includes securing pins with diameters of 5 mm, 6 mm, 8 mm, 10 mm, 12 mm and 16 mm.

Ball lock pins according to the version

The locking pins from norelem are available with different head and grip types. You can choose between pins with:

- L-grip

- Mushroom grip

- Adjustable mushroom grip

- Grip ring

- T-grip

- High shear strength

- Plastic collar or metal collar

Socket pins

At this point, we would also like to mention other types of pins that could be relevant for your applications: Socket pins. They can also be supplied by norelem as required.

A socket pin is a connecting element that is used in various applications and industries to connect or fasten components or parts together. Socket pins are often made of metal and have a cylindrical shape.

They are characterised by the fact that they can be inserted into corresponding holes or holders to establish a connection. In contrast to threaded screws or pins, socket pins do not require complex assembly with tools. Instead, they are simply inserted manually into the intended holders or holes.

There are different types of socket pins, each of which fulfils different requirements. Some socket pins have special locking mechanisms to ensure a secure connection and prevent unintentional loosening. These locking mechanisms can be ball locks, folding latches or other mechanisms.

The norelem range includes five different versions of socket pins.

- With mushroom grip

- With key ring

- With flat head and folding latch

- With flat head and axial lock

- With mushroom grip and magnetic axial lock

What is a ball lock pin?

Ball lock pins are self-locking pins that can be easily unlocked using a push button. These versatile connecting elements are known by various names, including:

- Locking pins

- Securing pins

- Ball lock pins

- Quick release pins.

Locking pins are used in numerous industries, whether for fixating, locking, connecting, adjusting or quickly changing between different positions.

A typical ball lock pin consists of a pin fitted with one or more balls. They engage in special holes in the base body of the pin when the pin is pushed into the correct position.

Use of ball lock pins offers several advantages:

- Ball lock pins ensure a secure connection and are ideal for applications where stability and safety are of crucial importance.

- The use of securing pins does not require any complicated assembly procedures or tools, which simplifies handling.

- The assembly and disassembly of components with locking pins is quick and easy, which increases efficiency in many applications.

- Ball lock pins generally do not require regular maintenance, which reduces the total operating costs.

What is the difference between a ball lock pin and a socket pin?

Ball lock pin are self-locking pins. They consist of a pin fitted with balls. They engage in special holes in the base body of the pin as soon as the pin is pushed into the correct position. This prevents unintentional loosening of the connection, even under load. In order to remove the ball lock pin, it must be pressed lightly and then pulled out to release the balls from the holes.

A socket pin, on the other hand, is a connecting element that is inserted into designated holders or holes to establish a connection. Socket pins do not normally have a self-locking function like ball lock pins. The connection with a socket pin is made by simply inserting it into the holder, and no additional locking is generally required. In order to remove the socket pin, it is usually simply pulled out.

Ball lock pins are therefore designed to create a particularly secure, self-locking connection, while socket pins offer a simpler and quicker way of connecting parts together. The choice between the two connecting elements depends on the specific requirements of your application.

How does a ball lock pin work?

As already mentioned, the ball lock pin is characterised by its self-locking function. The operating principle of the locking pin is relatively simple:

- The pin of the ball lock pin is fitted with balls.

- The balls are located in holes in the base body of the pin.

- When the pin is inserted into the corresponding holder or hole, the balls automatically engage in these holes as soon as the pin has reached the correct position.

- This prevents the pin from being pulled out of the connection without a specific unlocking movement being carried out.

- In order to remove the ball lock pin, it must be pressed lightly and then pulled out. This releases the balls from the holes and the connection can be cancelled.

Advantages of norelem ball lock pins

The ball lock pins from norelem are made from high-quality materials and manufactured under strict quality controls. This ensures the durability and reliability of the connecting parts.

The wide range of locking pins is also one of the advantages. In order to ensure that you find exactly the right product for your application, our range includes 33 different pins.

Overall, the ball lock pins from norelem offer a safe, reliable solution for fixating components in various applications. If you are looking for high-quality connecting elements, our ball lock pins are the right choice.